- Homepage

- Technology

- An Easy to Make Curved Image Sensor for Optoelectronics Origami

An Easy to Make Curved Image Sensor for Optoelectronics Origami

Do you know about curved Image Sensor? This is the generation of selfies, anybody and everybody these days from someone’s grandpa to their aunt, we’re all taking pictures. But are the pictures an actual representation of what we are truly seeing? Can they process images just as our eyes do?

The answer is no. While we do get pictures that are close to what we actually see, there is still a wide difference in what we are seeing and what is produced by a smartphone camera.

What is a Curved Image Sensor?

The reason why we don’t get pictures that are exactly the same as we see them is because of the camera’s image sensor. In all our smartphone’s camera, the image sensor is flat as opposed to our retina, which is the human version of an image sensor.

The flatness of the image sensor is why we get images that are lesser than what we see in life. All too often these flat sensors can’t process the images that they are seeing thus resulting in sub- par reproductions of reality.

Problems in making a Curved Image sensor:

While curved image sensors are not all that unheard of, it is the difficulties in manufacturing them that has prevented curved image sensors from becoming the norm.

One of the main problems in manufacturing has to do with trying to curve a rigid piece of silicon into the shape of a hemisphere without damaging or breaking the surface. This goes without saying, but any such damage to the image sensor will potentially affect the quality of images.

Overcoming the problem of making a curved image sensor:

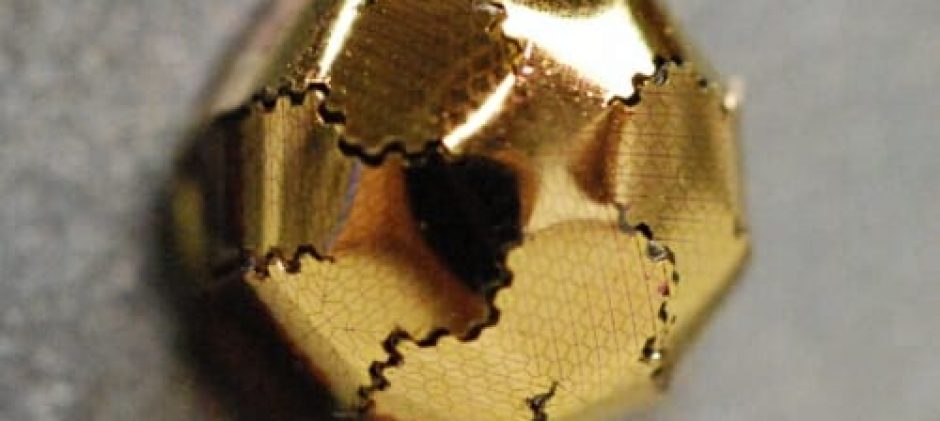

From origami to curved image sensors, researchers are using the traditional Japanese technique of paper craft to lend a curved shape to the image sensor.

Researchers placed pixels of various geometric shapes onto a flat flexible silicon surface called a nanomembrane. After that they used a laser to make the whole project a lot more seamless and then placed this nanomembrane surface onto a hemispherical shape to create the curved image sensor. This technique of making a curved image sensor can also be used to make other sorts of shapes as well.

Although their attempt at creating a curved image sensor has resulted in a sensor which is 7 millimeters in diameter, which is a little too big for a phone’s camera, they are confident that they can use the same technique to create a much smaller curved image sensor.

Benefits of a Curved Image Sensor:

With a curved image sensor, cameras can be made to offer virtually an infinite depth of field, lower aberrations, wider view angle, increased pixel density and more. In short, a camera with a curved image sensor will beat a flat one in taking pictures a lot better on any given day.